TEK7 SERVICES

Digitalization and

Smart Solutions

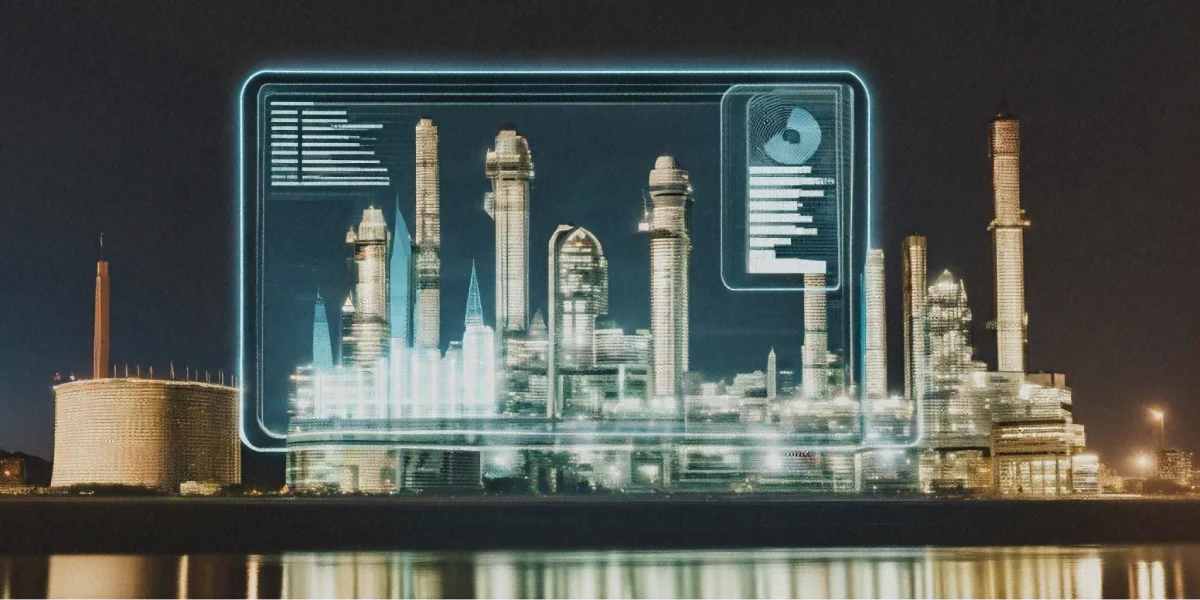

Digital Twins Development

TEK7 applies digital twin technology to create dynamic virtual models of physical assets. These real-time simulations enable clients to monitor equipment performance, predict maintenance needs, and test operational scenarios without disrupting production.

Our digital twins provide a comprehensive view of plant operations, helping identify inefficiencies and potential issues before they arise. By integrating sensor data, historical trends, and engineering models, we support smarter decision-making and proactive asset management.

This technology enhances operational reliability, reduces downtime, and optimises asset life, making it an essential tool for modern industrial plants seeking to improve performance and sustainability.

Data Analytics and Insights

At TEK7, we transform raw operational data into actionable insights that drive continuous improvement. Our data analytics services enable clients to understand performance trends, identify inefficiencies, and make informed decisions backed by evidence.

By applying advanced analytical tools and techniques, we uncover patterns and correlations within complex datasets. This empowers clients to optimise processes, reduce energy consumption, and improve overall plant productivity.

Our tailored analytics solutions support predictive maintenance, quality control, and operational benchmarking, helping clients stay ahead in a competitive and evolving industrial landscape.

Machine Learning Applications

TEK7 employs machine learning techniques to analyse large volumes of data and identify patterns that enhance process efficiency and reliability. By using AI-driven algorithms, we help clients predict equipment failures, optimise operations, and reduce unplanned downtime.

Our machine learning solutions support continuous improvement by enabling adaptive control strategies and smarter decision-making. This technology not only boosts operational performance but also contributes to cost savings and sustainability goals.

Through tailored machine learning applications, TEK7 empowers clients to unlock the full potential of their data and drive innovation in their industrial processes.

DC Pilot Platform

The DC Pilot Platform acts as a digital co-pilot alongside plant operators, providing centralised remote monitoring, control, and operational support. It integrates data from multiple sources, including sensors, control systems, and historical records, to deliver real-time insights that help operators make informed and proactive decisions.

Working alongside on-site teams, the platform enhances situational awareness by continuously analysing plant conditions and highlighting potential issues before they escalate. This leads to faster response times, reduced unplanned downtime, and optimised process performance.

The system also improves communication between operational and management teams by offering a single source of truth for plant status and performance metrics. Designed for complex industrial environments, it supports safer and more efficient operations while minimising the need for constant physical presence on site.

By combining advanced digital technologies with operator expertise, TEK7’s DC Pilot Platform helps clients improve reliability, increase productivity, and adapt quickly to changing operational demands.